As the demand for enhanced acoustic performance becomes increasingly prevalent across various industries, sound absorbing foam has emerged as an essential material for managing sound quality in both residential and commercial environments. According to a recent report by MarketsandMarkets, the global soundproofing materials market is projected to grow from USD 3.1 billion in 2020 to USD 4.8 billion by 2025, with sound absorbing foam playing a significant role in this growth due to its effectiveness in reducing noise and improving overall sound quality.

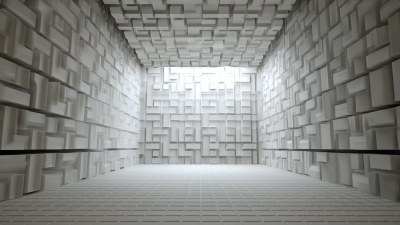

In 2025, the top sound absorbing foam types are set to provide innovative solutions tailored for specific applications, ranging from home theaters and recording studios to open office spaces and industrial settings. Research from the Acoustical Society of America indicates that the correct use of sound absorbing materials can reduce echo and reverberation by up to 50%, demonstrating the crucial role that sound absorbing foam plays in achieving optimal acoustic performance.

This article will explore the top ten sound absorbing foam types available in 2025, highlighting their unique properties, applications, and benefits. With advancements in technology and material science, choosing the right sound absorbing foam can significantly improve audio clarity and comfort in various environments, empowering users to create acoustically superior spaces.

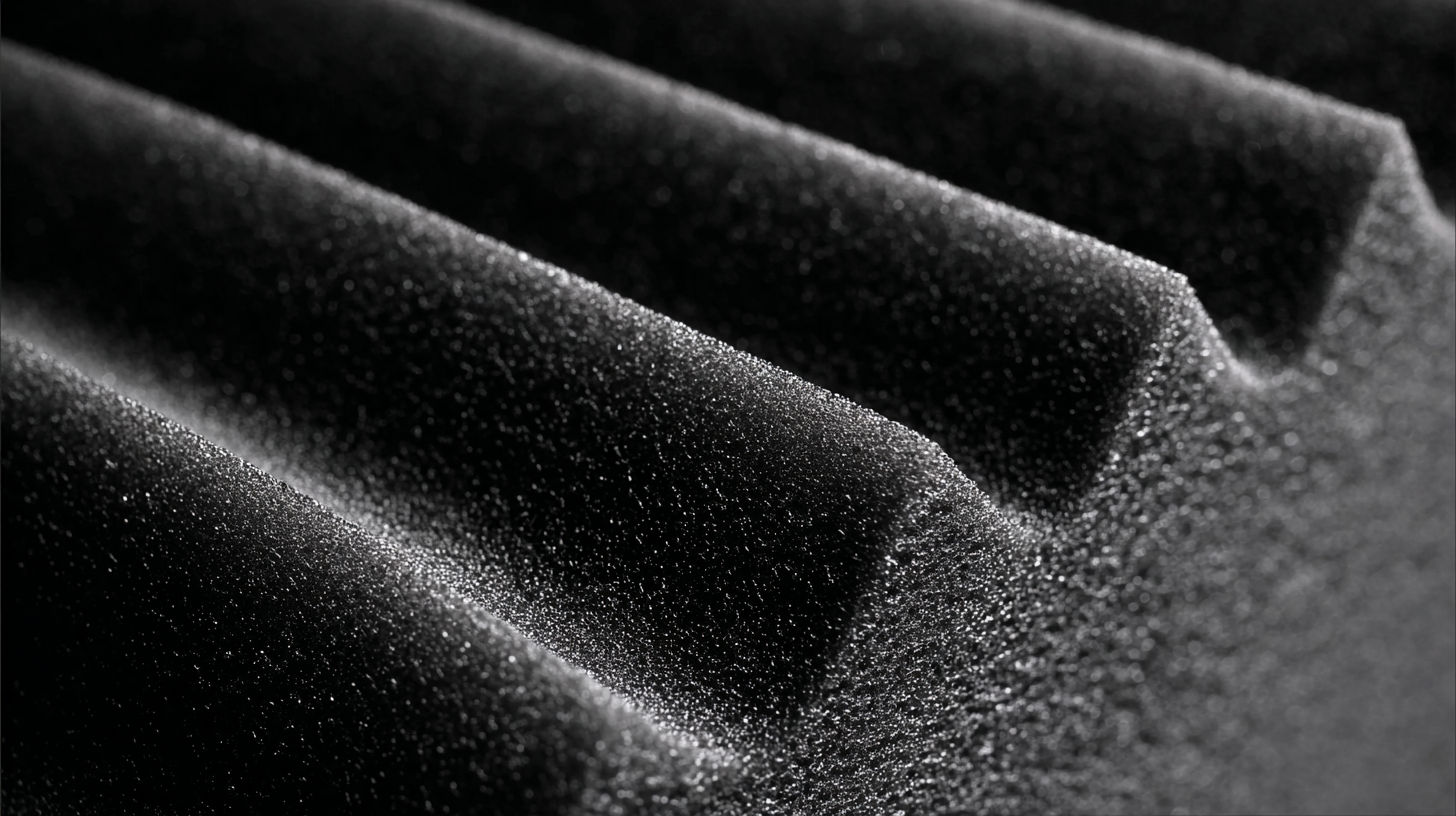

When considering sound absorbing foam for optimal acoustic control, it’s crucial to understand the various types available on the market. Among the most popular are polyurethane foams, known for their versatile applications in both commercial and residential settings. According to the Acoustical Society of America, polyurethane foams can achieve sound absorption coefficients of up to 0.95 in the mid-frequency range, making them an excellent choice for reducing echoes and improving clarity in music studios and home theaters.

Another prominent option is melamine foam, which offers exceptional sound absorption capabilities while also being fire-resistant. A report by the National Institute of Standards and Technology indicates that melamine foam can effectively reduce sound transmission by more than 20 decibels in certain frequency ranges. This makes it particularly suitable for industrial environments requiring both safety and acoustic control.

Lastly, fiberglass panels, known for their high-density structure, can also effectively manage sound waves, achieving an average sound absorption coefficient of around 0.80. These diverse foam types ensure that whether you are designing a recording studio or soundproofing an open office space, there are optimal solutions available to enhance acoustic performance.

The comparative analysis of open-cell and closed-cell foam materials reveals significant differences in their acoustic performance, particularly in sound absorption applications. Open-cell foams are characterized by their porous structure, allowing for greater air movement and sound wave penetration. This capability makes them highly effective for environments requiring sound dampening, such as recording studios and concert halls. The ability of open-cell foams to absorb sound is further enhanced by their lightweight nature and flexibility, which enable them to adapt to various spaces and applications.

In contrast, closed-cell foams offer different benefits, primarily excelling in sound insulation rather than absorption. The dense structure of closed-cell foam restricts air movement, which prevents sound waves from passing through, making it suitable for applications where noise reduction is essential, such as in industrial settings or between living spaces in residential buildings. While both foam types serve vital roles in acoustic management, the choice between open-cell and closed-cell foams ultimately depends on the desired acoustic environment and specific sound control needs.

When it comes to maximizing sound absorption efficiency, installation techniques play a crucial role. Proper placement of sound-absorbing foam can significantly enhance acoustic performance in any space. One effective technique is to strategically position the foam panels at the first reflection points on walls and ceilings. This involves identifying where sound waves first reflect off surfaces before reaching the listener’s ears. By addressing these key areas, you can effectively minimize reverberation and echo, leading to a clearer sound environment.

Additionally, varying the thickness and density of foam panels can create a more dynamic acoustic profile. Thicker panels can absorb lower frequencies, while thinner ones are more effective for higher frequencies. Combining different foam types not only optimizes sound absorption across a broad spectrum but also adds an aesthetic element to the room. Remember to leave sufficient air space behind the panels to maximize their effectiveness, as this allows for improved resonance. By applying these installation techniques, users can achieve a significant enhancement in acoustic performance, making spaces more enjoyable for listening, working, or performing.

When selecting sound-absorbing foam, the density of the material plays a crucial role in its acoustic performance. According to a report from the Acoustic Society, higher density foams, typically ranging from 4 to 8 pounds per cubic foot, are more effective in absorbing lower frequency sounds, such as bass notes from musical instruments or environmental noise. This density range is ideal for applications in recording studios or home theaters, where sound clarity is paramount.

On the other hand, lower density foams, usually around 1 to 3 pounds per cubic foot, are better suited for reducing high-frequency sounds, such as echoes and sharp sounds. These lighter foams are often recommended for use in spaces like offices or residential areas where overall sound dampening is desired without the need for extensive bass absorption. A balanced approach to foam density can significantly enhance the acoustic environment of any space, making it vital to choose the right foam for your specific needs and tailor your sound management strategies accordingly.

A recent study noted that properly chosen sound-absorbing materials could reduce noise levels by up to 30%, highlighting the importance of considering foam density and its applications for achieving optimal acoustic performance.

| Foam Type | Perfect Density (kg/m³) | Noise Reduction Coefficient (NRC) | Typical Applications |

|---|---|---|---|

| Open Cell Foam | 30-40 | 0.75 | Recording Studios, Home Theatres |

| Closed Cell Foam | 50-60 | 0.50 | Industrial Applications, HVAC Systems |

| Acoustic Panel Foam | 40-50 | 1.00 | Theatre Walls, Music Studios |

| Egg Crate Foam | 20-30 | 0.70 | Home Recording, Acoustic Treatment |

| Sound Barrier Foam | 80-90 | 0.80 | Commercial Spaces, Soundproofing |

To maintain the effectiveness of sound absorbing foam, regular maintenance is vital. Dust and dirt buildup can significantly reduce the foam's ability to absorb sound, so it's important to keep it clean. Start by gently vacuuming the foam using a brush attachment to remove dust particles without damaging the structure. For more thorough cleaning, consider using a damp cloth to wipe down the surface, ensuring that the foam is not soaked, as excess moisture can lead to mold growth.

Additionally, pay attention to the placement of your sound absorbing foam. Avoid exposing it to direct sunlight, which can degrade the material over time. Instead, position it in shaded areas or use window coverings to limit UV exposure. If used in areas with high humidity, consider applying a fabric protector spray that is suitable for sound absorbing materials. This will help maintain their performance and longevity, ensuring your acoustic environment remains optimal for years to come.